As one of the oldest and most versatile plants, hemp has been cultivated for thousands of years. In recent times, its use has expanded into a wide array of applications, ranging from textiles and construction materials to food and bioplastics. As the hemp industry continues to evolve, so do the innovative hemp manufacturing methods. This article delves into several breakthroughs in the hemp manufacturing space that demonstrate the potential for a more sustainable and eco-friendly future.

Advances in Hemp Fiber Processing

A significant area of innovation in the hemp maker sphere is the improvement of techniques to process hemp fibers. These advancements are essential to enhance efficiency and promote sustainability in the production of hemp-based textiles and materials.

Steam Explosion Process

The steam explosion process is an innovative method that uses high-pressure steam to separate hemp fibers from the woody core. This process significantly reduces the need for chemicals, leading to a more eco-friendly and cost-effective hemp manufacturing technique. The high-quality fibers obtained from the steam explosion process are not only stronger but also smoother, which makes them ideal for textiles and other industrial applications.

Enzymatic Retting

Another pioneering approach to hemp fiber processing is enzymatic retting. This method employs specific enzymes to break down the pectin and other bonding materials that hold hemp fibers together. Enzymatic retting provides an environmentally friendly alternative to water retting or chemical processing, which often leads to pollution and consumes vast amounts of water. Additionally, the process results in cleaner and finer fibers, which are more suitable for high-quality hemp products.

Innovations in Hemp Construction Materials

The ingenuity of these products manufacturers doesn’t end with textiles. Construction materials made from it have also experienced significant advancements, providing eco-friendly alternatives to traditional building materials.

Hempcrete

This is a groundbreaking construction material made from a mixture of hemp hurds, water, and a lime-based binder. It offers several benefits over conventional construction materials, such as excellent insulation properties, resistance to mold and pests, and reduced carbon footprint. Furthermore, the material is lightweight and breathable, making it a promising choice for sustainable construction.

Insulation

Another exciting development in the construction domain is hemp fiber insulation. This natural, renewable material is made from processed fibers and provides excellent thermal and acoustic insulation. Moreover, it is an eco-friendly alternative to synthetic insulation materials, contributing to healthier indoor air quality and reduced energy consumption.

Advancements in Bioplastics

The surge in environmental awareness has given rise to a demand for sustainable alternatives to traditional plastics. Enter hemp-based bioplastics, which have become an essential focus for hemp products manufacturers.

Biodegradable Plastics

Biodegradable plastics made from it are a remarkable innovation that aims to reduce plastic pollution. These materials are derived from hemp cellulose and are designed to break down over time, minimizing their environmental impact. Applications for hemp-based biodegradable plastics include packaging, disposable cutlery, and other single-use items.

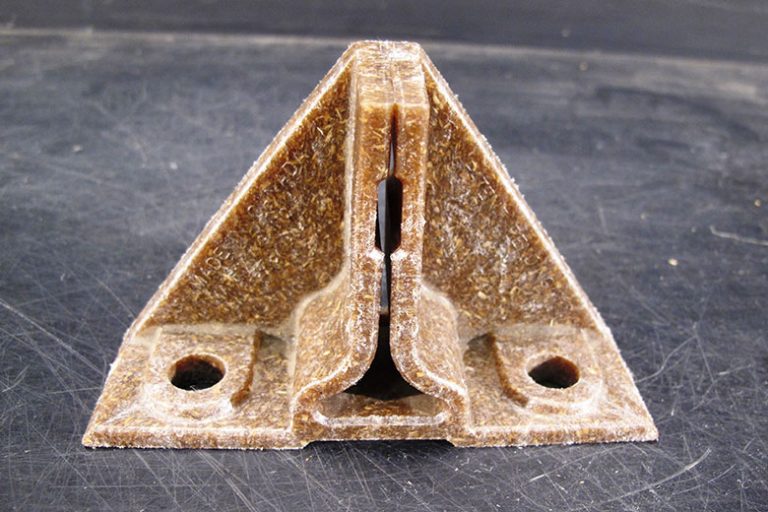

Biocomposites

Another intriguing development in the bioplastics arena are hemp Biocomposites. These materials combine hemp fibers with other biodegradable components, resulting in strong, lightweight, and environmentally friendly materials. They have already found applications in the automotive and construction industries, where they can replace traditional materials like fiberglass and carbon fiber.

Food and Nutritional Products

In addition to their numerous industrial applications, their seeds are also a valuable source of nutrition. Innovations in the extraction and processing of hemp seeds have given rise to several healthful food products.

Cold-pressed Oil

This is a nutritious and versatile product obtained through an innovative extraction process. This method involves mechanically pressing hemp seeds at low temperatures, ensuring that the valuable nutrients remain intact. The result is a high-quality oil rich in essential fatty acids, antioxidants, and vitamins. This is not only a healthy addition to a variety of dishes but also has potential applications in cosmetics and skincare products.

Protein Powder

This is a nourishing and sustainable alternative to other plant-based protein sources. This protein powder is produced by grinding the seeds into a fine powder, which is then used as a protein supplement. The powder boasts a complete amino acid profile, making it an ideal choice for vegans and those seeking a balanced and nutrient-dense source of plant-based protein. Furthermore, this protein powder is easily digestible and has a mild, nutty flavor, which makes it a popular addition to smoothies, baked goods, and other recipes.

Collaborative approaches and industry partnerships

Collaborative approaches and industry partnerships are playing a significant role in driving innovation in this product manufacturing. The industry is rapidly evolving, and businesses are recognizing the benefits of joining forces to leverage their expertise and resources. Through collaboration, companies can pool their knowledge, skills, and technologies to develop groundbreaking solutions and push the boundaries of hemp product manufacturing.

Partnerships between farmers, processors, manufacturers, and researchers are fostering innovation at every step of the supply chain. Farmers are working closely with researchers to develop new varieties with improved characteristics, such as higher fiber content or increased CBD production. Processors are collaborating with manufacturers to refine extraction and processing techniques, ensuring optimal yield and quality products.

Furthermore, industry partnerships are driving advancements in sustainability and eco-friendly practices. Manufacturers are teaming up with sustainability experts to develop methods for reducing waste, conserving resources, and adopting renewable energy sources in product manufacturing.

Collaborative approaches also extend beyond the industry itself. Partnerships with academic institutions, research organizations, and government agencies are facilitating knowledge exchange and providing access to funding for research and development initiatives.

Conclusion

As the hemp industry continues to expand, innovative hemp manufacturing methods are vital for unlocking its full potential. The advances in hemp fiber processing, construction materials, bioplastics, and food products offer promising opportunities for a more sustainable and eco-friendly future. These breakthroughs not only have a substantial impact on the environment but also hold the potential to transform the global economy. With ongoing research and development, we can expect to see even more revolutionary applications and advancements in hemp manufacturing in the coming years.